Mercedes impact sensor calibration ensures vehicle safety and efficiency by synchronizing data from advanced driver assistance systems (ADAS) sensors. This process aligns sensor readings with the car's computer system through CAN bus signal synchronization, crucial for accurate airbag deployment and crash severity assessment in collision repair. Accurate calibration enhances diagnostics, improves repair efficiency, and ultimately boosts customer satisfaction.

Mercedes impact sensor calibration is a critical process ensuring the safety and efficiency of modern vehicles. This article delves into the intricacies of calibrating these sensors, focusing on the essential role of CAN Bus signal synchronization. By understanding how data from impact sensors is collected and synchronized through the vehicle’s communication network, mechanics can perform precise adjustments for optimal performance. We explore best practices to correct sensory data, ensuring accurate analysis and reliable crash detection in Mercedes vehicles.

- Understanding Mercedes Impact Sensor Calibration

- Role of CAN Bus Signal Synchronization

- Correcting Sensory Data for Accurate Analysis

Understanding Mercedes Impact Sensor Calibration

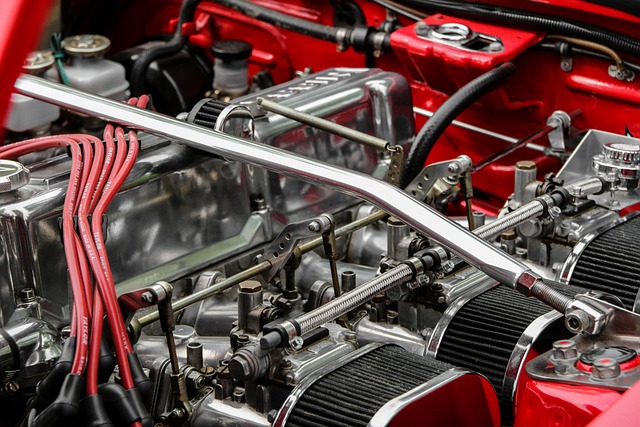

Mercedes impact sensor calibration is a critical process that ensures the safety and efficiency of modern vehicles. These sensors play a pivotal role in advanced driver assistance systems (ADAS), including collision avoidance, airbag deployment, and vehicle stability control. Calibration involves meticulously adjusting the sensor’s readings to match the specific requirements of the car’s computer system, ensuring accurate data transmission across various automotive body shop procedures, from routine maintenance to complex vehicle paint repair or automotive collision repair processes.

Proper calibration synchronizes signals sent through the CAN (Controller Area Network) bus, which connects multiple electronic control units (ECUs) in a vehicle. This synchronization guarantees that all ECUs receive identical and timely data, enabling seamless coordination during critical safety events. In an automotive collision repair scenario, for instance, accurate impact sensor readings can prevent incorrect airbag deployment or misjudged crash severity, thereby enhancing the overall safety of both occupants and other road users.

Role of CAN Bus Signal Synchronization

The role of CAN Bus Signal Synchronization in Mercedes impact sensor calibration is pivotal. This synchronization ensures that all data transmitted between various systems within the vehicle, including the impact sensor, are accurately timed and aligned. In an automotive repair context, especially for collision repair services, this precision is critical to ensure accurate readings and reliable diagnostics. An out-of-sync CAN Bus can lead to misinterpreted sensor data, compromising the integrity of post-collision assessments and potentially affecting safety-related repairs in an auto repair shop.

Proper synchronization harmonizes the communication between multiple electronic control units (ECUs) in the vehicle, enabling seamless exchange of real-time information. For Mercedes impact sensors, this means ensuring that the sensor’s data is accurately correlated with other systems’ inputs, such as airbag deployment timers and speed sensors. This synchronization not only enhances the accuracy of impact sensor calibration but also contributes to the overall effectiveness of automotive repair processes in collision repair services.

Correcting Sensory Data for Accurate Analysis

Accurate Mercedes impact sensor calibration is paramount for reliable vehicle diagnostics and safe operations, especially in modern cars equipped with sophisticated safety systems. During the calibration process, fleet repair services professionals must ensure that sensory data collected from various sensors is precise and synchronized. This involves meticulous adjustments to account for any drift or deviation in sensor readings over time. By calibrating these sensors, auto body repair experts can obtain consistent and accurate data, enabling them to analyze vehicle performance and identify potential issues effectively.

Correcting sensory data is a critical step in the calibration process, as it ensures that information from impact sensors aligns with real-world conditions. This synchronization is essential for fleet repair services, as it allows technicians to make informed decisions during maintenance checks and repairs, specifically in cases of car damage repair. With precise sensor data, mechanics can pinpoint problem areas more efficiently, leading to faster turnaround times and higher customer satisfaction.

Mercedes impact sensor calibration, especially with CAN bus signal synchronization, is paramount for ensuring accurate data analysis in vehicle safety systems. By correcting sensory data through this process, manufacturers can maintain the highest levels of precision and reliability, ultimately enhancing the overall safety and performance of Mercedes vehicles. Understanding and implementing proper calibration techniques, including synchronizing CAN bus signals, is crucial for keeping up with modern automotive standards and delivering top-tier results.